Izithambiso, njengempahla yabathengi yanamhlanje, ayifuni nje ukupakishwa okuhle, kodwa kunye nokukhuselwa kwemveliso ngexesha lokuthutha okanye kwishelufu.Idityaniswe novavanyo lokupakisha lwe-cosmetic kunye neemfuno zesicelo, izinto zokuvavanya kunye neendlela zokuvavanya zishwankathelwa ngokufutshane.

Ukuthuthwa kwezithambiso kunye novavanyo lokupakisha

Ukuze izinto zokuthambisa zifikelele kubathengi abakwimeko entle emva kokuhamba, umboniso weshelufu, kunye namanye amakhonkco, kufuneka babe nokupakishwa okufanelekileyo kwezothutho.Okwangoku, iibhokisi ze-carton zisetyenziselwa ukupakisha izinto zokuthambisa, kwaye amandla oxinzelelo lwebhokisi kunye novavanyo lokupakisha zizalathi zayo eziphambili zovavanyo.

1.Uvavanyo lokupakisha ibhokisi

Ngexesha lokugcinwa kunye nokuthutha, iibhokisi kufuneka zifakwe.Ibhokisi ephantsi kufuneka ithwale uxinzelelo lweebhokisi ezininzi eziphezulu.Ukuze ingawi, kufuneka ibe namandla afanelekileyo oxinzelelo emva kokupakisha, ngoko ukupakisha kunye noxinzelelo oluphezulu Ukufumanisa iindlela ezimbini zokuwa kwamandla kubaluleke kakhulu.

2.Uvavanyo lokungcangcazela kothutho olufanisiweyo

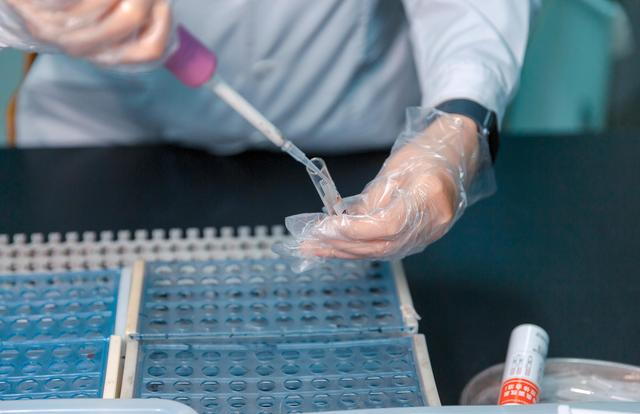

Ngethuba lokuthutha, emva kokuba ukupakishwa kuqhutywe, kunokuba nefuthe elihambelanayo kwimveliso.Ke ngoko, kufuneka senze umfuniselo wokulinganisa ukungcangcazela kwemveliso: lungisa imveliso kwibhentshi yovavanyo, kwaye uvumele imveliso iqhube uvavanyo lokungcangcazela phantsi kwexesha elihambelanayo lokusebenza kunye nesantya sokujikeleza.

3.Ukupakishwa kovavanyo lokulahla

Imveliso ngokuqinisekileyo iya kuwa ngexesha lokuphatha okanye lokusetyenziswa, kwaye kukwabalulekile ukuvavanya ukuxhathisa kwayo.Beka imveliso epakishweyo kwingalo yenkxaso ye-drop tester, kwaye wenze uvavanyo lwamahhala lokuwa ukusuka kumphakamo othile.

Ukuhlolwa komgangatho wokupakishwa kweCosmetic

Izithambiso zinobuhle obubonakalayo obubonakalayo kwaye zonke ziprintwe kakuhle, ngoko ke kubaluleke kakhulu ukuvavanya umgangatho wokushicilela.Okwangoku, izinto zesiqhelo zokuhlolwa komgangatho woshicilelo lwezithambiso kukuxhathisa kwe-abrasion (i-anti-scratch performance) yomaleko we-inki yoshicilelo, ukubhaqwa kokukhawuleza kokuncamathelisa, kunye nokuchongwa kombala.

Ucalucalulo lwemibala: Abantu badla ngokujonga imibala ekukhanyeni kwelanga, ngoko ke umsebenzi wocalucalulo lombala ocolekileyo kwimveliso yemizi-mveliso ufuna umthombo wokukhanyisa ube nokusasazwa kwamandla okubonwa okumalunga nokukhanya kwelanga lokwenyani, oko kukuthi, umthombo wokukhanya osemgangathweni we-D65 ochazwe kwiCIE.Nangona kunjalo, kwinkqubo yokudibanisa umbala, kukho into ekhethekileyo kakhulu: isampuli kunye nesampuli iya kubonakala kumbala ofanayo phantsi komthombo wokuqala wokukhanya, kodwa kuya kubakho umehluko wombala phantsi komnye umthombo wokukhanya, obizwa ngokuba isenzeko semetamerism, ngoko umgangatho wokhetho Ibhokisi yemvelaphi yokukhanya kufuneka ibe nemithombo yokukhanya emibini.

Ukuchongwa kweleyibhile ye-cosmetic self-adhesive

Iileyibhile zokuzincamathelisa zisetyenziswa kakhulu kwipakethe yokuthambisa.Izinto zokuvavanya ubukhulu becala kuvavanyo lweempawu zokubambelela kwiileyibhile zokuzincamathela (i-self-adhesive okanye i-adhesive-sensitive adhesives).Izinto eziphambili zokuvavanya zi: ukusebenza kokuqala kokubambelela, ukunamathela Ukusebenza, amandla e-peeling (amandla e-peeling) izibonakaliso ezintathu.

Amandla e-Peel luphawu olubalulekileyo lokulinganisa ukusebenza kwebhondi yeelebhile zokuzincamathela.Thatha umatshini wokuvavanya i-electronic tensile okanye umatshini wokuvavanya i-electronic peeling njengomzekelo, ileyibhile yokuzincamathela inqunyulwe ibe yi-25mm ububanzi ngemela yesampuli, kunye neleyibhile yokuzincamathela ihlanganiswe kwi-plate yovavanyo oluqhelekileyo kunye ne-roller yokucinezela eqhelekileyo, kwaye ke isampuli kunye nepleyiti yovavanyo ziqengqeleka kwangaphambili.Ukuxobula, beka ibhodi yovavanyo kunye neleyibhile yokuncamathela kwangaphambili ehlutshiweyo kwindawo ephezulu nasezantsi okanye ekhohlo nasekunene yovavanyo olukrelekrele lwe-electronic tensile okanye umatshini wokuvavanya amaxolo e-elektroniki ngokulandelelanayo.Misela isantya sovavanyo ukuya kwi-300mm/min, qalisa uvavanyo lokuvavanya, kwaye ubale amandla okugqibela e-peel KN/M.

Ukufunyanwa kwezinye izibonakaliso zomzimba kunye noomatshini bokupakishwa kwezithambiso kunye nezixhobo zokupakisha

Iipropathi zoomatshini bokupakishwa kwezithambiso zidlala indima ebaluleke kakhulu ngexesha lokupakishwa, ukusetyenzwa, ukuthuthwa, kunye nobomi beshelufa yezithambiso.Umgangatho wayo umisela ngokuthe ngqo ukhuseleko lokutya kwi-circulation.Shwankathela zonke izinto zovavanyo ikakhulu zibandakanya: amandla okuqina kunye nobude, ukomelela kwefilimu ehlanganisiweyo, amandla okutywinwa kobushushu, ukutywinwa kunye nokuvuza, ukuchasa impembelelo, ukuguda komphezulu wezinto kunye nezinye izalathi.

1.Amandla okuqina kunye nobude, ukomelela kwe-peel, amandla okutywina ubushushu, ukukrazula ukusebenza.

Amandla e-tensile abhekiselele kumthamo omkhulu wokuthwala wemathiriyeli phambi kokwaphuka.Ngolu phawu, ukuphulwa kwephakheji kunye nokuphulwa okubangelwa amandla anganeleyo omatshini wezinto ezikhethiweyo zokupakisha zingasombululwa ngokufanelekileyo.Amandla e-Peel ngumlinganiselo wamandla okudibanisa phakathi kweeleya kwifilimu edibeneyo, eyaziwa ngokuba yi-composite fastness okanye amandla adibeneyo.Ukuba amandla okunamathela aphantsi kakhulu, kulula kakhulu ukubangela iingxaki ezinjengokuvuza okubangelwa kukwahlulwa phakathi kweengqimba ngexesha lokusetyenziswa kokupakisha.Amandla okutywinwa kobushushu ngamandla esitywina sokubona, okwakwaziwa njengamandla okutywinwa kobushushu.Kwinkqubo yokugcinwa kwemveliso kunye nokuthutha, xa amandla okutywinwa kobushushu aphantsi kakhulu, kuya kubangela iingxaki ezifana nokuqhekeka kwesitywina sokushisa kunye nokuvuza kwezinto eziqulethweyo.

2.Uvavanyo lokumelana nempembelelo

Ukulawulwa kwempembelelo yokuchasana kwezinto zokupakisha kunokuthintela ukwenzeka komonakalo kwindawo yokupakisha ngenxa yobunzima bezinto ezingonelanga, kwaye ngokufanelekileyo uphephe umonakalo wemveliso ngenxa yokuxhatshazwa kwempembelelo embi okanye ukwehla kokusebenza kwezinto zokupakisha kwinkqubo yokujikeleza.Ngokubanzi, kuyimfuneko ukusebenzisa umvavanyi wempembelelo yedart kuvavanyo.Umvavanyi wempembelelo yebhola ewayo umisela ukuchasana kwempembelelo yeefilimu zeplastiki ngendlela yebhola ewela simahla.Olu luvavanyo olukhawulezayo nolulula olusetyenziswa ngabenzi bokupakisha bezithambiso ezininzi kunye nabavelisi bezithambiso ukuvavanya amandla afunekayo ukukrazula isampuli yefilimu phantsi kweemeko ezichaziweyo zempembelelo yebhola ewa simahla.Amandla okuphulwa kwephakheji xa i-50% yesampuli yefilimu ingaphumeleli phantsi kweemeko ezichaziweyo.

3.Uvavanyo lokuxhathisa isitshizi setyuwa

Xa imveliso ithunyelwa elwandle okanye isetyenziswe kwiindawo eziselunxwemeni, iya kutshatyalaliswa ngumoya wolwandle okanye inkungu.Igumbi lovavanyo lokutshiza ityuwa lelonyango lomphezulu wezinto ezahlukeneyo, kubandakanya iingubo, i-electroplating, ifilimu ye-inorganic kunye ne-organic, i-anodizing, kunye ne-oyile echasene nomhlwa.Emva konyango lwe-anticorrosion, vavanya ukuxhathisa kwe-corrosion yemveliso.

Somewang Packaging,Yenza ukuPakisha kube lula!

Ixesha lokuposa: Sep-16-2022